Production Stages

Design office

The Design office consists of one in-house design staff and two freelance design staff.

More than 400 new designs are renewed for each of the collections.

Product customization upon customer request.

Printing

Over the past few years, the company has invested in printing on fabrics. It is now possible to print any pattern or sketch on a white polyester fabric. This technology allows unlimited creativity and thus opens up the world of customization. The BOSSI company is now fully independent in the creation of its designs.

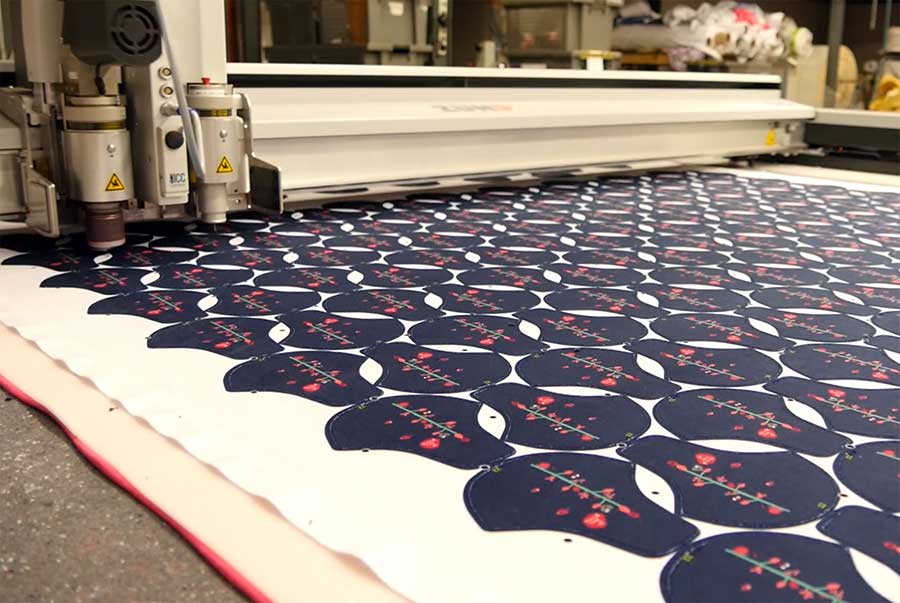

Cutting

The company also masters knife-clicking. This technique allows the production of small quantities and a high flexibility in the creation of designs.

The various integrated processes are :

• Manual – die-cutting

• Automatic cutting

• Digital cutting

Customization

We also master the technology of positioning transfers and the one of embroidery as well as the placing of badges.

All these new skills allow us to be more responsive and autonomous.

Stitching

The stitching is fully made in our Dordogne workshop. This know-how is widely recognised by our customers, as our partnerships with major brands can attest.

It includes the binding, the assembly and also the placing of the insole.

Injection

It is not less than 10 injection machines, equipped with an automatic PVC colouring system, giving us the possibility to offer an unlimited choice of colours.

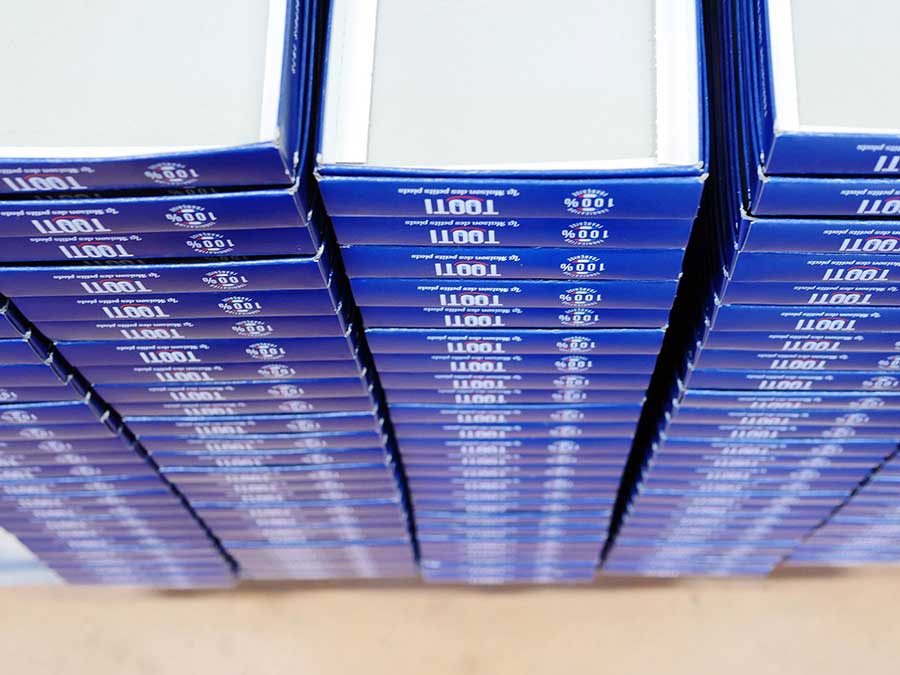

Control & Packing

Our quality department increasingly checks each project we do carry out.

We have storage facilities and permanent inventories made for some of our customers.